Victall has developed a proprietary manufacturing process that incorporates spiral welding. Spiral welding is a more challenging production technique which can bring good benefits for the finished products. Spiral welded perforated tubes are used as support filter cylinders or tubes for filter elements made with woven wire mesh fabrics as filter media. Fine opening welded tubing is also used to work singly as well screen or sand control screen for water treatment.

Spiral welded perforated tube materials: stainless steel 304, 316, 316 L.

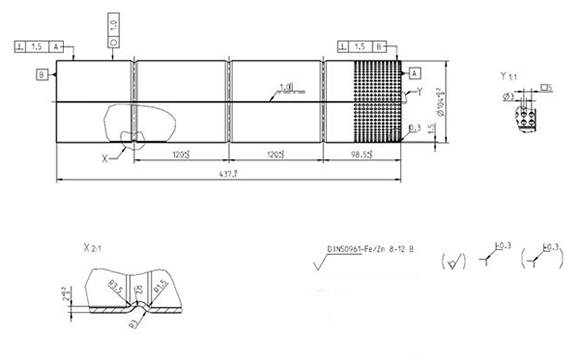

The tube Specifications:

* The diameter: 50-300mm

* The thickness: 0.8-3mm

* The length: less than 10m

* The hole type: bridge, round hole and so on.

The specifications and materials of hole punching can be produced and installed in accordance with the needs of users.

Features:

* Excellent corrosion-resisting

* Tubes are available with an internal spring for additional strength

* With side opening exterior protection cover (optional)

* Unique design of filter ring

* Spiral welded perforated tube is approximately 15% stronger than longitudinally and welded tube

* Easy for installation and less work time

* Unlimited tube lengths

* Lighter wall thickness can be used